Improvement of productivity

Improving productivity and quality of products and goods is considered as a vital factor that identifies the existence and development of enterprise(s).

The application of national standards, technical regulations, productivity improving tools, quality management system…is an important solution for enterprise(s) to improve productivity and quality.

- How to improve productivity?

- How to optimize production time and balance the steps during the production process?

- What is the matter existing in your company’s management process?

- Do you want to quickly improve productivity for your departments or company?

“Improvement of Productivity” training course focuses on identifying the matter existing in the factory that affects overall productivity. This matter is considered to be vital to factories today. The training course will help learners understand the practical methods that are necessary to solve specific matters during the production management process of their factories.

COURSE OVERVIEW

PURPOSE OF COURSE

- To understand the pillar of ideal lean production.

- To optimize time and balance of production steps.

- To improve the bottling step to maximize productivity.

- To innovate the management process to build ideal production activity.

TRAINING CONTENT IN THE COURSE

1. Identifying matters

- What is efficient manufacturing?

- What is Tact time, cycle time?

- Manufacturing process

- Total net output

- Productivity analysis

- Choice of topic

- Practice: Calculating power of the process

- Practice: Effective calculation and balance analysis

2. Understanding current status and setting up targets

- What is understanding current status?

- Typical losses

- Setting up targets and planning

- Practice: Identifying and measuring losses by 5W2H

3. Analysis of current status

- What is current status analysis?

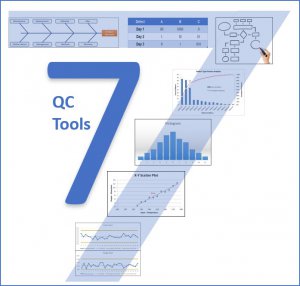

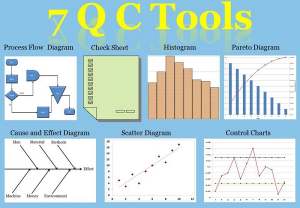

- Typical loss analysis method

- Practice on current status analysis

4. Identifying origin of cause

- What is origin of cause?

- Productivity improvement points

- Practice on problem analysis

5. Identifying and selecting implementing option

- Productivity improvement points (continued)

- Additional lecture

6. Evaluation of results and standardization

- Steps of report development

- Practice on report development

7. Selecting next topic and report presentation

FEEDBACK